Building Integrated Photovoltaics (BIPV) are modern materials that replace conventional materials as part of a building’s structure and also incorporate photovoltaic (PV) components, which are used to generate electricity or heat.In recent years BIPV materials have been commonly used in parts of the building envelope such as the roof, skylights, or facades. Globally the growth of solar (PV) production capacity rose 40-fold in the 10 years to 2014 and significant growth in solar PV production capacity is expected to continue for the next 20 plus years.Trac Group specialises in the design, supply and distribution of BIPV products. In particular, our Tractile products fit into the Roof Integrated Photovoltaic (RIPV) and the Roof Integrated Photovoltaic and Thermal (RIPV-T) sector. Our RIPV-T products create electricity and generate hot water using solar energy. Our products integrate solar (PV) power into multifunctional building components to enhance a structure’s functionality without impacting its aesthetics.Interestingly Tractile significantly outperforms concrete tiles and metal sheet roofing. The “Composites: Calculating their Embodied Study” led by Queensland’s Department of Employment, Economic Development and Innovation (DEEDI). The report found that:

- A square metre of roofing that is made from Tractile roof tile consumes 92% less energy than a concrete tile and 99.5% less energy than a coated steel sheeting during their life cycle if they are maintained;

- A square metre of roofing that is made from Tractile roof tile emits 90% less greenhouse gases than a concrete tile during their life cycles and 99.2% less greenhouse gases than coated steel sheeting during their life cycles if they are maintained;

- A square metre of roofing that is made from Tractile roof tile has an environmental impact which is 89% less than that of a concrete tile and 99.2% less than that of a coated steel sheeting if they are maintained. This equates to a lessening on the effects towards human health, the ecosystem quality and resource use during their life cycles.

- Tractile tiles are engineered to withstand live loads between battens in excess of 250kg. (In comparison other roofing materials break or deform at 60kg-100kg).

- Tractile tiles are light. One Tractile roof tile is six times larger than a concrete tile, and weighs 8kg versus 4kg – 5kg for a single concrete tile (the weight of concrete roof tiles depends on its design with flat profile tiles using less concrete than wavy profile tiles). This equates to a weight of 12kg per square metre for Tractile versus 40kg – 50kg per square metre for concrete roof tiles.

- Tractile tiles have high impact resistance. All Tractile tile products (excluding solar tiles) are rated for impacts of 100 Joules. A 100 Joules impact is equal to being hit with a 68 millimetre hailstones (a tennis ball has diameter of 67mm), or hitting the tile with a 1kilogram hammer at 14 metres per second (normal speed for a 1 kg hammer to hit objects is 8 to 12 metres per second).

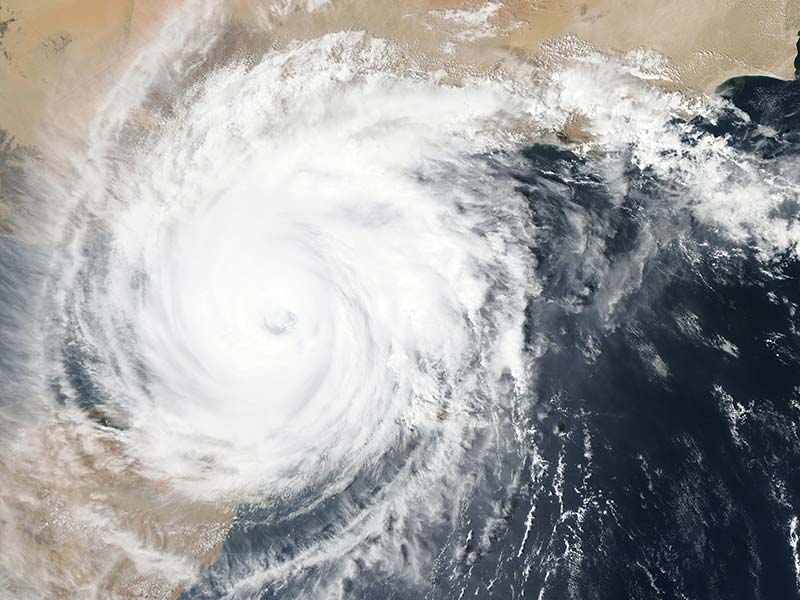

- Tractile tiles are engineered to withstand wind speeds of over 300km per hour (Category 5 Tropical Cyclones 280 km/h) but as a stand-alone product is rated C4, which is the highest rating possible. C5 rating is only possible for entire roof structures.

- The composite material used to manufacture Tractile products is non-electrically conducting, which minimises the risks of electrical hazards.

- The composite material used to manufacture Tractile products is non-toxic, which provides for safety when handling and cutting.

- Tractile has fire retardant qualities.

- The materials and the manufacturing process allow for greater design freedom.

- The composite materials do not rust.